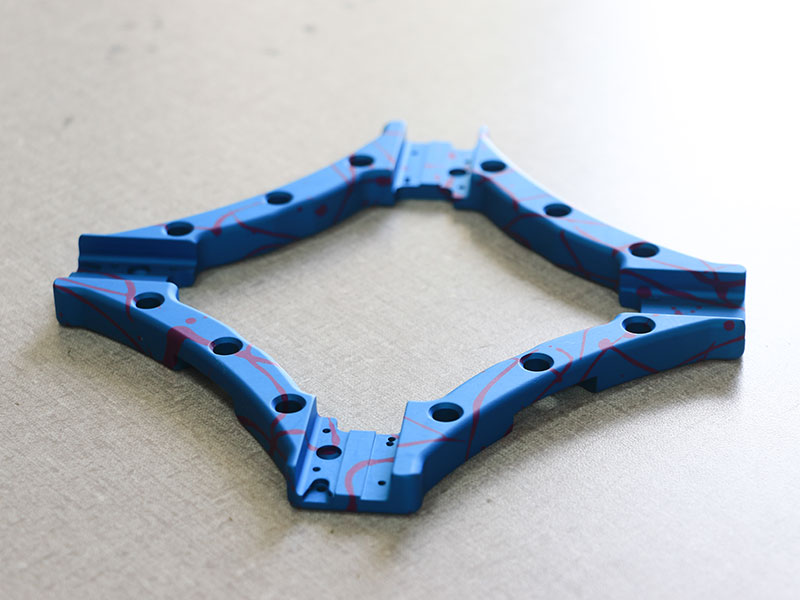

Our core strength lies in our ability to support our customers in design, prototyping, and manufacturing.

From start to finish, West Coast Surgical offers complete design, manufacturing, and production assembly of surgical devices and instrumentation, having years of in-the-field experience while adhering to all regulations bringing your product to the market.

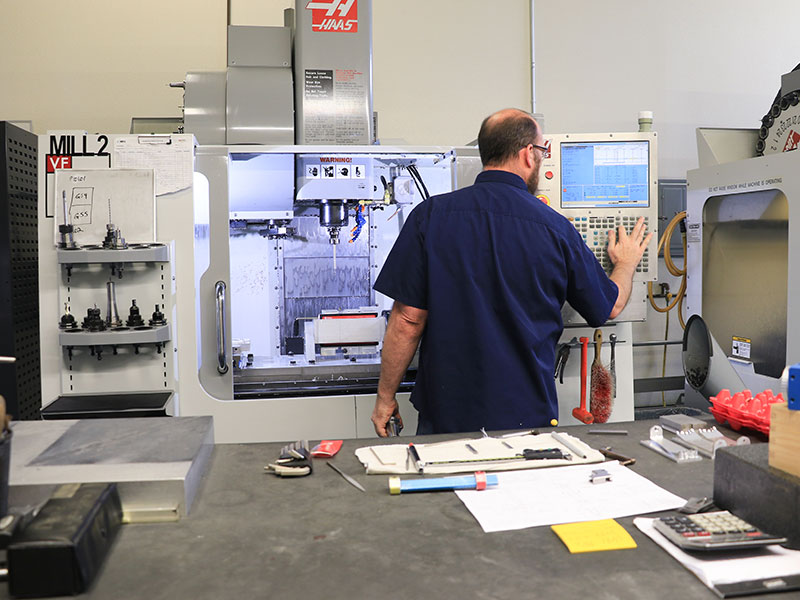

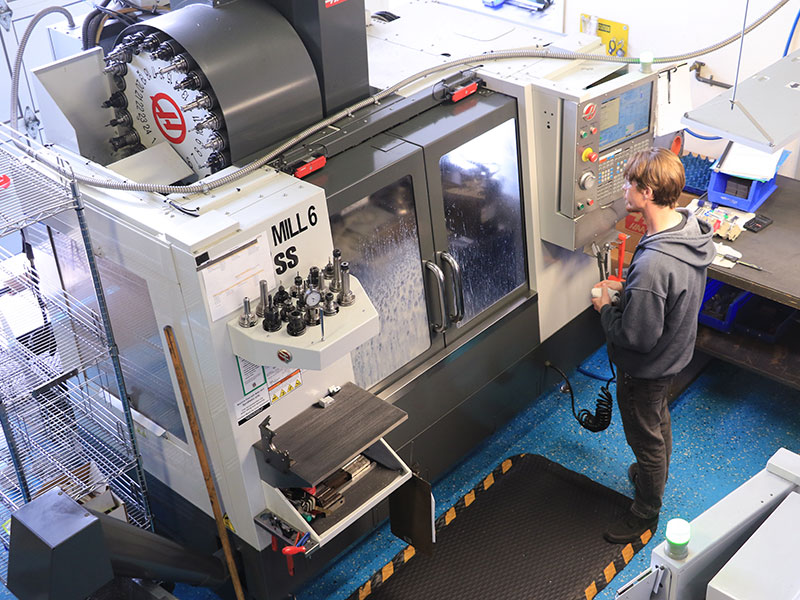

West Coast Surgical is a complete manufacturing facility. Our in-house machining, finishing, and assembly departments allow us to take a customer's new or existing product from print to production.

We're able to take a customer's concepts and/or device needs and pair them with our experience and library of designs and mechanisms to develop a manufacturable and fully functioning production device.

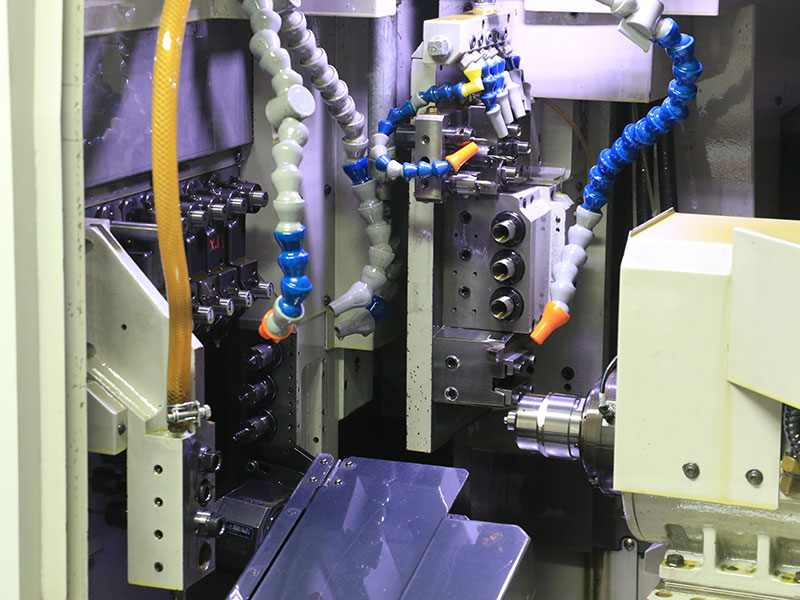

With our Swiss lathe, we are able to mill, drill, ream, and do other operations within the machine.

Unlike 3 axis machining, the cutting tool stays tangential to the surface you are cutting. More material is removed with each pass of the tool and the requirement for less set-ups result in saved time and saved cost.

Electrical discharge machining (EDM), allows us to cut fine, complex, and precise features that may be difficult for a standard milling machine.

Lorem ipsum dolor sit amet, consectetuer adipiscing elit, sed diam nonummy nibh euismod tincidunt ut laoreet dolore magna aliquam erat volutpat. Ut wisi enim ad minim veniam, quis nostrud exerci tation ullamcorper suscipit lobortis nisl ut aliquip ex ea commodo consequat. Duis autem vel eum iriure dolor in hendrerit in vulputate velit esse molestie consequat, vel illum dolore eu feugiat nulla facilisis at vero eros et accumsan et iusto odio dignissim qui blandit praesent luptatum zzril delenit augue duis dolore te feugait nulla facilisi. Lorem ipsum dolor sit amet, cons ectetuer adipiscing elit, sed diam nonummy nibh euismod tincidunt ut laoreet dolore magna aliquam erat volutpat. Ut wisi enim ad minim veniam, quis nostrud exerci tation ullam